Guide to Corrugated Boxes

Pack it, Ship it, Store it!

Having the right box for your products can be a huge factor in how successful a purchase was. Whatever you’re shipping, you want to ensure products arrive safely to your customers. What is the best box strength for your product? This guide will help you determine why corrugated material is a great shipping option over traditional cardboard.

What is Corrugated Material?

Corrugated material, or often referred to as corrugated fiberboard, consists of cellulose fibers that are placed in layers, creating different levels of protection. These elements are classified as “medium” or “fluting” that is attached to the “lining” through adhesion.

Based on the number of flutes and linings, these corrugated boxes are identified as either single-wall, double wall, or triple-wall. The fluting provides extra strength that can withstand the wear and tear throughout the packing, shipping, and storage process.

Corrugated vs. Cardboard

Corrugated boxes are strong, durable packaging containers that are used to ship a variety of products. They are made of layered materials that help support contents during shipping and storage.

Cardboard cartons are made of thick stock paper. Most retailers use cardboard boxes for shipments, but that comes with a risk of having little protection to your products. Using cardboard boxes could require bubble wrap, sheets, or loose fill to help secure items during shipments, where corrugated boxes wouldn’t require this.

What is the major difference between cardboard vs. corrugated boxes?

- The materials used to build each type of box are different. Corrugated boxes are made of layers of paperboard, while cardboard is one sheet of heavy-duty paper or paperboard.

- The sturdiness of the two types. Flutes within corrugated boxes provide durability, while cardboard can be bent easier due to being only one layer thick.

4 Benefits of Using Corrugated Material

There are numerous benefits of corrugated boxes. Choosing the best type of box for your products will ensure items are delivered safely to its destination. Here are four benefits of corrugated boxes:

1. Protection

Corrugated material is very protective and durable, especially compared to regular cardboard boxes. They act as another layer of protection during shipping. These boxes are designed to keep moisture and bacteria away from products within the box. When shipping food contents, these boxes are a great solution to ensure freshness.

2. Cost-effective

Corrugated boxes are a cost effective shipping box because of how cheap it is to produce and easily can be recycled. They have low manufacturing costs.

3. Reusable

Corrugated boxes are reusable and can be easily recycled since they are made from biodegradable materials. They are then processed to produce new material for new boxes. Corrugated boxes can have a ‘Corrugated Recycles’ symbol that is used worldwide to prompt users to recycle the boxes. They are made of 70-100% recycled materials, making it one of the most eco-friendly packaging options for you.

4. Lightweight

Corrugated boxes are lightweight, yet durable. This makes it convenient for suppliers so they won’t get overcharged on shipping weight.

The Composition of Corrugated Material

The composition of a corrugated box can be either single, double, or triple wall. Corrugated boxes have different flute sizes that provide additional protection. Based on the type, boxes go through a certification testing to provide the best type of protection to products. Which type of best is best for you?

Corrugated Wall Types

Single Wall

Single wall cardboard is the most common between the different types of corrugated boxes. This consists of an out and inner layer with fluting in between the two layers.

Double Wall

Double wall cardboard has two full layers of fluting. This makes it extremely durable for shipping and storing needs.

Triple Wall

Triple wall cardboard has three full layers of fluting and is commonly used for items that need more care during transportation.

Package Certification Testing

Boxes are put through a series of tests to see how much weight each type can hold. Determining this strength allows items to be safely shipped and stored.

Edge Crush Test (ECT)

The ECT measures the vertical compression rate of a box to see how it will hold up being stacked. It’s a reliable test for ensuring products will remain intact during transit. Today, most products are shipped on pallets, and boxes need to hold the weight of the items within.

Mullen Burst Test

The mullen test measures the vertical strength of the corrugated material along the edge of a package. Developed over 130 years ago, the test focuses on the amount of force applied before it bursts. The results are given in pounds with a rating to show how much weight the box can hold. This is a useful test to ensure that products will not get damaged throughout the shipment process.

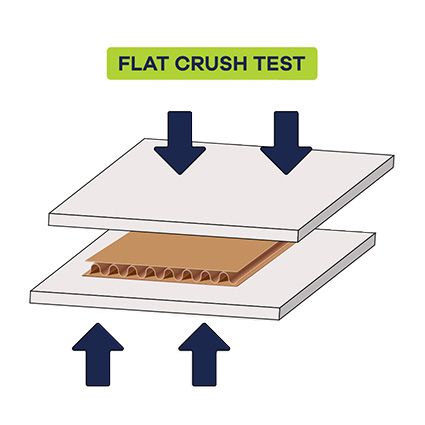

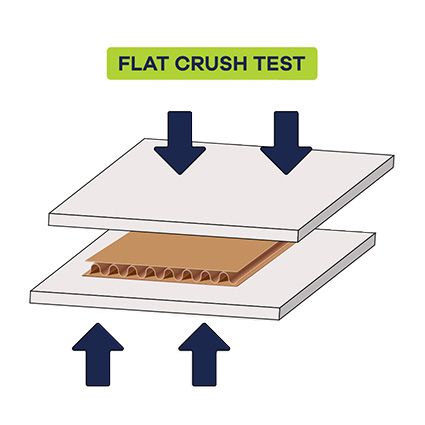

Flat Crush Test (FCT)

The flat crush test measures how much crush the flute material can handle in order for your packages to resist damage. This is helpful in determining the amount of pressure that corrugated boxes can hold.

Box Ratings Based on Weight

Selecting a box that is sturdy enough for your needs is important. Use these charts to determine what strength box you need for your products.

Single Wall

| Mullen Burst Strength | Edge Crust Test (ECT) | Max Weight Limit/Carton |

| 125 # | 23 ECT | 20 lbs. |

| 150 # | 26 ECT | 35 lbs. |

| 175 # | 29 ECT | 50 lbs. |

| 200 # | 32 ECT | 65 lbs. |

| 275 # | 44 ECT | 95 lbs. |

| 350 # | 55 ECT | 120 lbs. |

Double Wall

| Mullen Burst Strength | Edge Crush Test (ECT) | Max Weight Limit/Carton |

| 200 # | 42 ECT | 80 lbs. |

| 275 # | 48 ECT | 100 lbs. |

| 350 # | 51 ECT | 120 lbs. |

| 400 # | 61 ECT | 140 lbs. |

| 500 # | 71 ECT | 160 lbs. |

| 600 # | 82 ECT | 180 lbs. |

Triple Wall

| Mullen Burst Strength | Edge Crush Test (ECT) | Max Weight Limit/Carton |

| 700 # | 67 ECT | 240 lbs. |

| 900 # | 80 ECT | 260 lbs. |

| 1100 # | 90 ECT | 280 lbs. |

| 1300 # | 112 ECT | 300 lbs. |

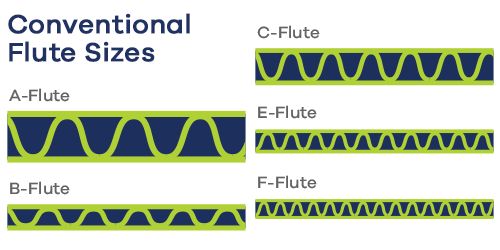

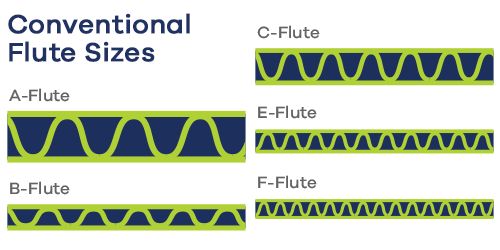

Flute Sizes

Corrugated material is made up of three fiberboard layers, two linerboards with a wave-shaped material called flutes. These flutes are adhered to the boards. The flutes provide additional support to products during shipping, storage, or transportation. Flutes also protect against temperature changes.

The most common flute size is A. The thicker the flute, the more protection it provides. Smaller flute sizes provide additional structural and printing capabilities, which is useful for retail packaging.

The 5 common flute sizes:

- A-Flute: about 36 flutes a foot, thickness: 1/4"

- B-Flute: about 49 flutes a foot, thickness: 1/8"

- C-Flute: about 41 flutes a foot, thickness: 3/16"

- E-Flute: about 90 flutes a foot, thickness: 1/16"

- F-Flute: about 128 flutes a foot, thickness: 1/32"

Choosing the Right Corrugated Box

Corrugated packaging is a good solution for several reasons. If you have heavier, bulkier, or fragile items, then a corrugated box should be your packaging solution to provide durability and protection during shipments.

Corrugated boxes are great for:

- Books

- Clothing

- Shoes

- Car parts

- Sports equipment

- TVs

- Artwork

- Paintings

- Toys

- Cosmetics

- Mirrors

- Golf Clubs

Customization and Design Options for Corrugated Boxes

Being able to customize corrugated boxes helps with your company’s awareness. These boxes can easily be branded, leaving a great impression on those that are receiving the products.

Whether you have an amazing design in your head or have no clue where to start, our designers are here to help. We’ll create a mockup of your label before it’s printed so it looks exactly how you imagined. The Cary Company offers design services to make your dream packaging a reality. Reach out to our creative team at 630.629.6600 or email sales@thecarycompany.com to schedule a free consultation to start the design process.