The Importance of Label Design

Labels, Please!

Packaging is one of the most important ways to communicate with customers. It is crucial to understand the role that label design plays in the success of a product, as it can make all the difference in attracting customer attention and ultimately drive sales.

Creating your story on a label will help with brand identity and create brand trustworthiness. There are hundreds of labels customers see a day, but what will make yours stand out?

1. Unique Label Design to Attract the Buyer's Attention

Once you have a clear understanding of your target audience and what they are looking for, it’s time to start thinking about the design of your label. The label design should be unique and eye-catching, as it’s the first thing a customer will see when they come across your product.

Bright colors, fonts, imagery, and clear messaging will make your labels stand out. Creating a story around your product can help customers connect emotionally with your brand which creates trust.

People are attracted to unique packaging. This can be based on looks or how the product feels. Creating an aesthetically pleasing label design will speak to your customers and leave a lasting impression.

2. Understanding What Your Customers Want in the Label Design

The design of your label should reflect an experience you want your customers to have. Lables that understand the needs and preferences of your target audience, allows you to point out specific features that they value.

For example, if you are targeting more health-conscious consumers, you should highlight the better alternative ingredients that they might be searching for when buying items. By understanding your target audience, you can tailor your label to speak directly to them.

3. Type of Label Applications

It’s time to label your containers! But which type of label application is best? Label Applications include label machines, in-mold labeling, and the use of flame treatment will prepare your containers to properly adhere the labels.

Label Machines

Label machines quickly and accuretely apply labels to your contintainers. We carry an assortment of label printers and dispensers to help give your containers the attention it deserves. Use label machines for:

- Paint Cans - We can apply custom paint can labels on plastic, hybrid, or tin paint cans ranging from 1/2 pint to 1 gallon.

- Cylindrical Containers - Our cylindrical labeling machine can handle containers from 0.5” to 10” in diameter and up to 16” tall.

- Flat Sided and Uniquely Shaped Containers - Not every product can be applied via a label machine. For those items, our team can apply your labels for you!

In-Mold Labeling

Companies within the food, personal care, household, and cosmetic industries often use In-Mold Labeling (IML) to apply their labels. This method provides high-resolution colors and images to your containers. It is very durable, water resistant, environmentally friendly, and cost-effective.

The two most commonly used plastic types used to manufacture a container with in-mold labeling are high density polyethylene (HDPE) and polypropylene (PP).

Types of in-mold labeling:

- Injection Molding (Pictured above) - In injecting molding, the design label is placed into the mold before fusing together with the container. After the plastic pellets are heated, the resin is injected into the mold where it seamlessly combines with the label.

- Blow molding - Blow molding is similar to glass blowing. Like injection molding, the label is inserted into the mold before it is combined with the plastic. However, instead of injecting plastic into the mold, it is blown in using an air stream. Once expanded into the desired shape, the label melds to the container.

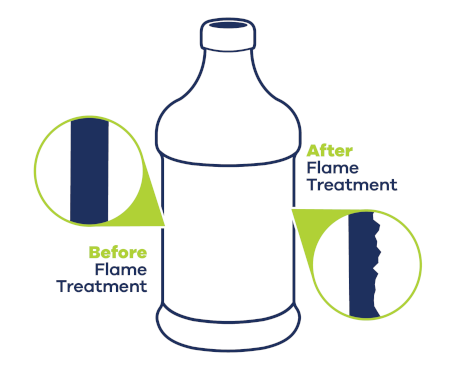

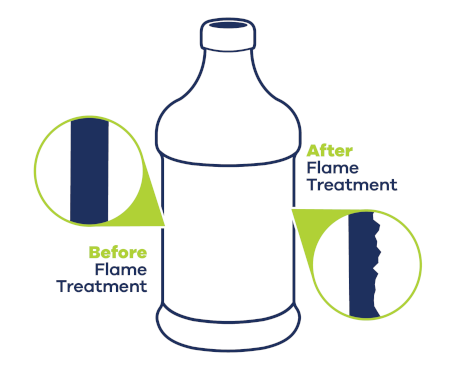

Flame Treatment

The use of flame treatment for label adhesion can be used on high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP) containers. If the surface is not treated properly, then your label will not stick.

As the container is exposed to this flame:

- Dirt, dust, fibers, oils and other contaminants that can also affect adhesion are removed.

- The plastic's surface is activated by breaking the molecular chains and adding polar functional groups.

This process creates a "rougher" finish that allows your label to stick to the surface of the container. Ideally, labeling should take place shortly after treatment.

Creating a Custom Experience

If you are selling directly to the customer, consider taking a step further by creating a custom packaging experience by adding your brand logo onto your shipment boxes. This enables a luxurious experience for your consumers which will create a lasting impression.

Browse our Guide to Boxes to see which is best for your products and ways to reduce your shipping costs with your packaging. Corrugated Boxes protect contents within and are great for shipping and storage of products. We offer boxes that can be customized to enhance awareness of your brand.

SHOP ALL RESHIPPER BOXES

Ready to Upgrade Your Label Design?

At The Cary Company, we understand the importance of label design and offer a wide range of packaging solutions. If you need help putting your idea on paper, we offer custom design services to meet your packaging needs.

Our in-house design team can take your ideas and create designs from scratch so that it's made exactly as you envision it. Contact Us -- Call 630.629.6600 or email us at sales@thecarycompany.com